Ships are the go-to mode of transportation for most of the world’s goods. Unfortunately, their high sulphur- and carbon-intensity does not bode well for a climate positive future. With the commodity trading industry still largely dependent on maritime freight, the bodies responsible for coordinating and regulating international trade have introduced various policies aiming to align shipping with global climate goals. At the same time, ways to expand inland freight capabilities continue to be explored, although the feasibility of such plans vary between continents.

The seascape: sustainable shipping practices

The main sustainability issue with ships is that they produce a lot of air and sea pollution. Most of us are used to hearing about carbon emissions when it comes to global warming, but with ships the main culprits are sulphur oxide species. Fuel (crude) oil contains sulphur which is why burning fuel oil releases gaseous sulphur oxide into the atmosphere.

As you would expect, the first policies introduced by the International Maritime Organisation (IMO) and International Convention for the Prevention of Pollution from Ships (MARPOL) aim to cut sulphur oxides emissions.

Compared to where we are today, the MARPOL protocol was just the beginning of the initiatives to tackle shipping related global warming. Adopted in 1997, the protocol details the resolutions of the conference of the same name which include:

- A code for the control of nitrogen oxides emissions

- Monitoring of and ways to address sulphur content on residual fuel oils used on board ships

- Restricting the use of perfluorocarbons on board ships

- CO2 emissions from ships1

The IMO kicked off 2020 by limiting sulphur concentration in fuel oil used on ships outside emission control areas (ECA) to 0.50% m/m (mass by mass) – even lower than the original limit of 3.5% m/m which was introduced eight years prior.

n June 2022 the Marine Environment Protection Committee held its 78th session in which it approved the Mediterranean Sea as an ECA for sulphur oxides. This means that from 2025 ships calling at almost all European ports will have to pass through ECA designated waters and comply with the stricter emissions policies which limit the sulphur content in fuel oil used on board ships to 0.10% mass by mass (m/m) compared to 0.5% m/m outside of the ECA. Other significant developments include strengthening its initial GHG reduction strategy to address the needs of small island developing states and least developed countries.2

Most shipping companies have swapped out high sulphur fuel oil for very low sulphur fuel oil (VLSFO) to meet the requirements of the IMO 2020 sulphur cap. Others who chose to stay with the non-compliant high sulphur fuels needed to fit exhaust gas cleaning systems to remain compliant with the IMO 2020 sulphur cap regulations. Still, carbon is a significant greenhouse gas (GHG) released from ships, and in its initial Greenhouse Gas Strategy the IMO sets out ambitions for a 40% reduction in CO2 intensity by 2030, a 70% reduction by 2050, and a 50% reduction in all GHG by 2050.

How businesses are adopting new technologies for greener shipping

The Sustainable Shipping Initiative has expressed that the industry needs to have a portfolio of techniques and technologies to shift industry energy efficiency. Wind assistance and air lubrication tech are the two areas of focus they have explored. Wind assistance tech can include parasails, which cut fuel usage by using wind to gain traction instead of fuel rotors. While air lubrication of hulls involves trapping a layer of air bubbles between the hull seawater in order to reduce resistance and therefore the propulsive power needed. The SSI has tested different air lubrication and wind assistance solutions on the market and found they can potentially cut energy consumption by double digits and can be cost effective.3

Another way to improve shipping energy efficiency is to tackle biofouling.

Biofouling and using slime management for more efficient shipping

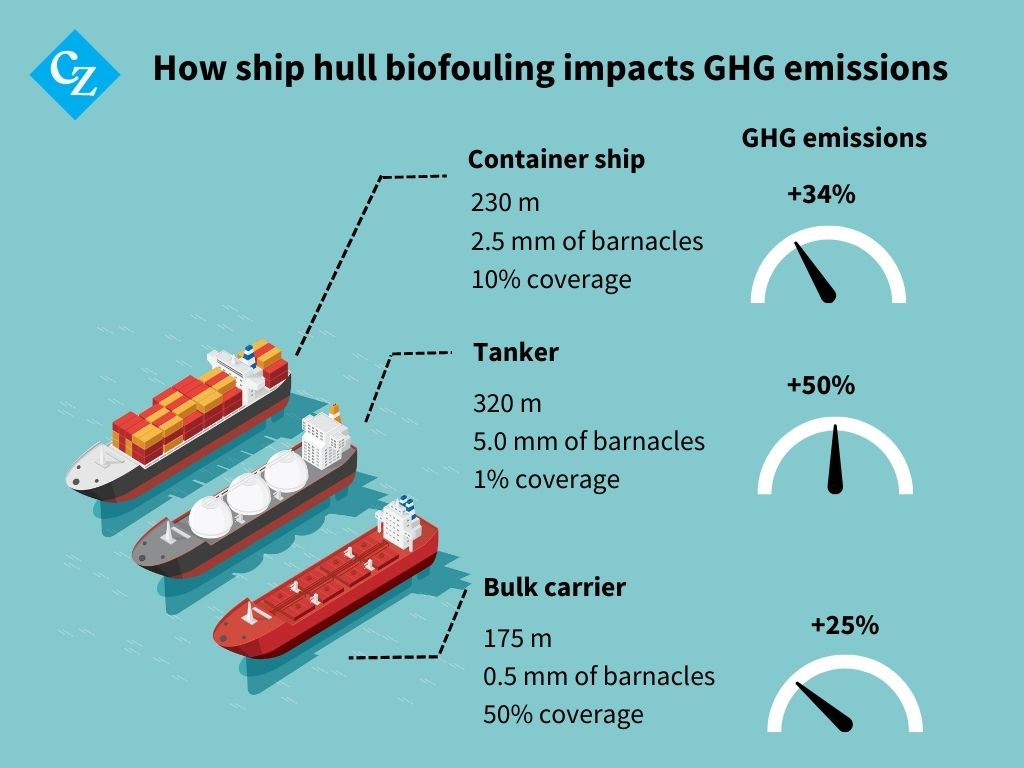

Biofouling is what we call the unwanted build-up of organisms on surfaces, you may also hear it called ‘slime’. When the surfaces of a ship that serve a mechanical function – typically the hull – are covered with microorganisms, plants, or small animals, it faces more resistance which means it will need to consume more fuel to move at an appropriate speed. At COP26 in 2021, Global Industry Alliance (GIA) for Marine Biosafety shared the preliminary results of a research they conducted which showed that biofouling can increase GHG emissions of up to 55% depending on the ship’s specifications and voyage conditions.4 To give you an idea of how impactful slime can be, 0.5 mm of slime on half of the hull surface can increase GHG emissions by 20 – 25%.

Naturally the next step is to work at managing biofouling. One way is to develop an advanced ship’s hull coating system. These low-resistance, sometime biocidal, hull coatings are typically polymers and more effective for reducing hydrodynamic resistance than the traditional coatings. This approach also requires regular monitoring and reapplication because hull coatings degrade over time. Interestingly, the type of coating that does not kill the biofouling-causing organisms can provide the smoothest hulls; these are the fluoropolymer foul release coatings.5 Some shippers may choose to combine new coatings with more hull cleaning to reduce roughness.

The thing that makes hull coating systems attractive is the applicability to existing ships and their cost. It’s estimated that a hull coating system can cost between US$ 30,000 – 50,000 per ship which is a lot cheaper than buying a new ship, for comparison a bulk carrier can cost between US$ 10 – 15 million. Perhaps we will see more shipping companies adopting this method.

Sustainable shipping innovations

IMO fuel mandates are just one part of sustainable freight forwarding since they only apply to shipping. Here are four other solutions to investigate and potentially invest in.

- Move more products by rail

Another solution to make freight more sustainable is to pivot toward inland freight, specifically rail. Freight trains are less carbon intensive than trucks and ships because they use less fuel, making them cheaper. We are also seeing trains become more reliable and punctual than they were at the beginning of the millennium. According to the Rail Freight Group, each freight train removes up to 76 lorries from the roads, resulting in 1.6 billion fewer HGV kilometres every year.6 As more locomotives use electric traction engines, which alone generate no pollution, rail freight could gain more traction as greener transportation.

But there are two major limitations to this option: a, not every country has the infrastructure needed to make this a reality, and b, trains are limited in how much cargo they can carry.

China uses rail more than other transportation thanks to its an extensive standard gauge rail network capable of moving 4.4 billion tonnes of cargo in 2019, according to the Ministry of Transport for the People’s Republic of China.7 Similarly, the USA, though not known for its commuter rail lines, has one of the best railways for moving cargo.

The challenge with opting for rail comes when trying to move cargo between countries with different and incompatible rail networks. It is common to be delayed at cross border points when there is a need to change train operators, a frequent issue within Europe. - Engineer more fuel-efficient cargo ships

Before ships ran on crude oil they ran on coal. Now we are on the verge of another ‘Propulsion Revolution’, one that could see vessels run on hydrogen/ammonia or battery powered by renewable energy. The clear benefit of hydrogen/ammonia fuelled ships is that they are zero-carbon. However, there will always be a need for a ship operator will need to always evaluate how changing ship fuel it will affect propulsion, the mechanisms used to move a ship across water, because propulsion is the key to a functioning ship.

The Ship Energy Efficiency Management Plan (SEEMP), another IMO measure, provides operators with a mechanism to improve energy efficiency while being cost effective. When used with the Energy Efficiency Operational Indicator (EEOI), it is possible to monitor how changes effect operation, and use this knowledge to improve voyage planning.8

Much like when electric cars were first introduced and drivers were hesitant to buy in because of limited charging points, vessel owners (especially those of bulk carriers) may not be ready to invest until there are sufficient charging or hydrogen fuelling stations available. Why bulk carriers especially? Bulk ships don’t have a direct route a lot of the time which means they don’t know when they will get a chance to refuel, unlike container ships which go from one port to another, without other ports in-between. It is easier to place hydrogen and charging stations at busier ports with regular traffic than at every port, especially in the early days of the transition. - Redesign and build new cargo ships

Existing vessels were not designed for the zero-carbon future desired. One way to get closer to a decarbonised maritime industry is to replace the existing fleet with more energy efficient vessels. The IMO’s Energy Efficiency Design Index (EEDI) requires certain vessels to meet minimum energy efficiency standards according to the type of ship and size segment it is designed to operate within. The EEDI promotes the use of more energy efficient equipment and engines to achieve as much as 30% reduction of vessel CO2 emissions per tonne mile by 2025,8 and no doubt will be updated to achieve greater reductions beyond that date. Designing vessels and engines to run on alternative fuels comes with its benefits and limitations. Although less GHG intense than biodiesel, electricity would not necessarily be a viable source of power until there are advances in capacity enabling vessels to cover the long distances between ports where charging facilities might be available.

Cargo ships are massive investments; they cost tens of millions of dollars and historically would have been expected to have an operating lifespan of around 25 years which means owners need a degree of certainty over the regulatory landscape within which the ships will operate before committing to newbuild designs and energy efficiency specifications to ensure that the vessels ordered today remain commercially relevant in the future, therefore enabling owners to make a return on the initial investment. At the same time decommissioning and recycling commercial ships can be costly, so perhaps incentives will need to be offered to scrap ageing vessels from the fleet to achieve the lower carbon targets - Streamline logistics to reduce the ship transit times

Changing fuel or running ships on electricity may prove to be effective innovations, but one clear way to cut down emissions is to reduce the amount of time wasted. Of course, achieving this is more complex in practice. Ships can be delayed because of port congestions, equipment shortages or lack of coordination between relevant parties. Optimising maritime supply chains may require more automation, personnel and competition.

Examples of voyage optimisation measures to help reduce emissions are:

a) Slow streaming: low streaming: operating vessels below their maximum speed to fuel consumption significantly.

b) Weather routing; this is exactly what it sounds like – finding the route with the ideal winds, waves and ocean currents for the ship’s specifications and cargo demands in the hopes of reducing fuel consumption.

c) Trim optimisation. Trim is the floating position of a ship in length direction. Trim optimisation is when you select the trim position for the vessel to experience less resistance which means it would need less propulsive power.

d) Virtual arrival (this one really piqued our interest): virtual arrival systems aim to end the practice of ‘sail fast then wait’ that has become rather popular in the shipping industry. The system operator advises the vessel when a berth will be available so they can determine the optimal speed and route to take in order to arrive on time and avoid waiting at the port.9

Zero emissions shipping?

When we look at the pace with which the IMO has been releasing new environmental policies, it’s clear that we can expect more changes to come the closer we get to 2050. More governments are likely to introduce stringent laws about shipping pollution. The European Union has already mandated CO2 emissions monitoring for vessels that weigh more than 5000 MT.

We are at the point where freight companies are taking more action than they ever have and most of it is out of necessity. Still zero emissions shipping is unlikely by 2050, and one of the reasons for this is the absence of a clear roadmap for getting there. The legislation on maritime pollution has not been finalised yet and not every country has committed to the existing policies. Therefore, we should keep in mind that not all the solutions being used by shipping companies will be unsuitable within the decade. So, expect the solutions to evolve with more research and development and fluid demand for freight.

Did you like this blog? Share it on Linkedin, Facebook, or Twitter.

If you want to more to know more about supply chains and global trade, you may like some of the recommended content below. Or explore our back catalogue yourself.

Sources

- International Maritime Organization, International Convention for the Prevention of Pollution from Ships (MARPOL). Accessible at: International Convention for the Prevention of Pollution from Ships (MARPOL) (imo.org)

- International Maritime Organization, 2022, Cutting ships’ GHG emissions – working towards revised strategy. Accessible at Cutting ships’ GHG emissions – working towards revised strategy (imo.org)

- Sustainable Shipping Initiative, 2013, A step change in energy technology innovation and uptake. Accessible at A step change in energy technology and innovation uptake: Final report – Sustainable Shipping

- International Maritime Organization and GloFouling Partnership, 2021, Preliminary results Impact of Ships Biofouling on Greenhouse Gas Emissions. Accessible at Biofouling report.pdf (imo.org)

- Gold Standard, 2016, Reducing Vessel Emissions Through the Use of Advanced Hull Coatings (Version 2.0). Accessible at CDM: Proposed new methodology. Meth Panel recommendation to the Executive Board. (Version 03.1) (goldstandard.org)

- Rail Freight Group, Why use rail freight. Accessible at: Why use rail freight? – Rail Freight Group (rfg.org.uk)

- Ministry of Transport for the People’s Republic of China, 2020, 2019 Railway statistical bulletin (Chinese). Accessible at: 国家铁路局关于发布《2019年铁道统计公报》的公告-铁路-中华人民共和国交通运输部 (mot.gov.cn)

- International Marine Organization, Energy Efficiency Measures. Accessible at; Energy Efficiency Measures (imo.org)

- United States Environmental Protection Agency, 2022, Virtual Vessel Arrival Systems at Ports Improves Air Quality and Saves Fuel. Accessible at: Virtual Vessel Arrival Systems at Ports Improves Air Quality and Saves Fuel | US EPA